Detroit Manufacturing Systems (DMS) stands at the forefront of automotive manufacturing innovation, driving excellence in the production of complex automotive components. In an era where efficiency and quality are paramount, DMS has positioned itself as a leader in the industry, delivering state-of-the-art solutions that cater to the needs of major automotive clients. This article will explore the evolution of Detroit Manufacturing Systems, the technologies they employ, their impact on the automotive landscape, and future trends that could shape the industry.

Founded in 2013, DMS has quickly become a pivotal player in the manufacturing sector, especially in the heart of the automotive capital, Detroit. The company specializes in producing high-quality automotive components, leveraging advanced manufacturing techniques and a skilled workforce. With a commitment to excellence and innovation, DMS has established a reputation that speaks volumes about its capabilities and contributions to the automotive industry.

As we delve into the intricacies of Detroit Manufacturing Systems, we will uncover the various elements that contribute to its success. From its innovative production methods to its dedication to sustainability, each aspect of DMS is designed to meet the evolving demands of the automotive market. Join us as we embark on a comprehensive exploration of DMS and its significant role in shaping the future of automotive manufacturing.

Table of Contents

- The History of Detroit Manufacturing Systems

- Vision and Mission of DMS

- Technology and Innovation at DMS

- Manufacturing Process at DMS

- Sustainability Practices

- Strategic Partnerships and Collaborations

- Impact on the Automotive Industry

- Future Trends in Manufacturing

- Conclusion

The History of Detroit Manufacturing Systems

Detroit Manufacturing Systems was established in response to a growing need for high-quality automotive components manufactured in the United States. The company was founded by a group of industry veterans who recognized the potential of leveraging Detroit's rich automotive heritage and skilled workforce. Since its inception, DMS has focused on delivering precision-engineered components that meet the stringent quality standards of leading automotive manufacturers.

Key Milestones in DMS History

- 2013: DMS is founded, focusing on automotive component manufacturing.

- 2014: DMS secures its first major contract with a global automotive manufacturer.

- 2016: Expansion of production facilities to accommodate increasing demand.

- 2018: Implementation of advanced manufacturing technologies, including robotics.

- 2020: DMS achieves ISO 9001 certification for quality management.

Vision and Mission of DMS

The vision of Detroit Manufacturing Systems is to be the leading provider of automotive components in North America, recognized for quality, innovation, and customer service. The mission is to deliver world-class manufacturing solutions that exceed customer expectations while fostering a culture of continuous improvement and sustainability.

Core Values

- Quality: Commitment to delivering superior products.

- Innovation: Embracing new technologies and methods.

- Customer Focus: Ensuring client satisfaction through tailored solutions.

- Sustainability: Promoting environmentally friendly practices.

Technology and Innovation at DMS

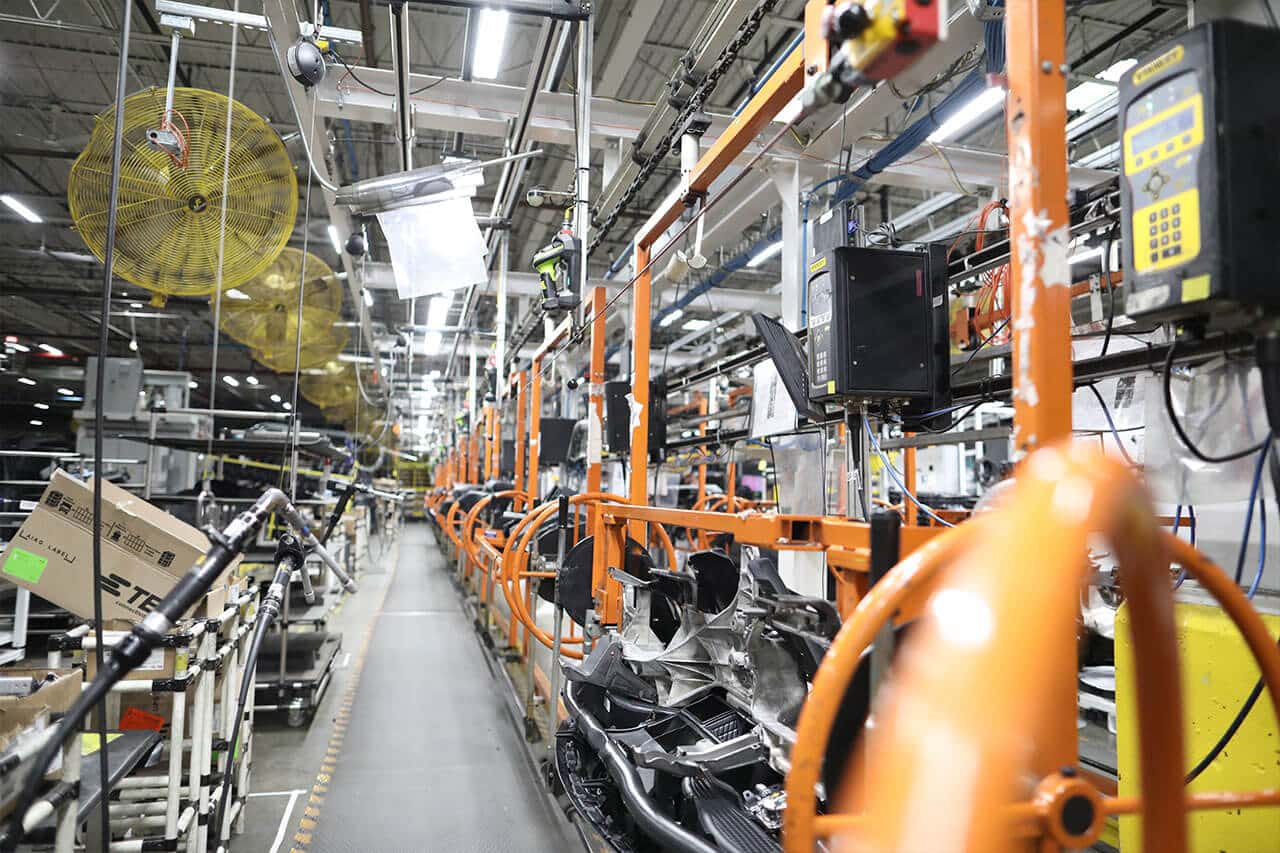

Detroit Manufacturing Systems employs cutting-edge technology to enhance its manufacturing processes. By integrating automation and advanced manufacturing techniques, DMS improves efficiency, reduces waste, and ensures product quality.

Advanced Manufacturing Techniques

- Robotics: Utilization of robotic systems for precision assembly and material handling.

- 3D Printing: Rapid prototyping and production of complex components.

- IoT Integration: Smart manufacturing solutions that allow real-time monitoring and data analysis.

Manufacturing Process at DMS

The manufacturing process at Detroit Manufacturing Systems is designed to maximize efficiency while maintaining high-quality standards. The company uses a combination of lean manufacturing principles and advanced technology to streamline operations.

Steps in the Manufacturing Process

- Design and Engineering: Collaborating with clients to create detailed product specifications.

- Material Sourcing: Selecting high-quality raw materials from trusted suppliers.

- Production: Utilizing advanced machinery and skilled labor for component manufacturing.

- Quality Control: Implementing rigorous testing and inspection processes.

- Logistics: Efficiently managing the distribution of finished products to clients.

Sustainability Practices

Detroit Manufacturing Systems is committed to sustainable manufacturing practices. The company recognizes the importance of minimizing its environmental impact and actively seeks ways to reduce waste and energy consumption.

Initiatives for Sustainability

- Energy Efficiency: Implementing energy-saving technologies in production facilities.

- Waste Reduction: Recycling materials and reducing scrap during manufacturing.

- Green Certifications: Pursuing certifications that reflect commitment to sustainability.

Strategic Partnerships and Collaborations

DMS has forged strategic partnerships with various organizations and suppliers to enhance its capabilities and expand its market reach. These collaborations enable DMS to access new technologies and improve its product offerings.

Notable Partnerships

- Collaboration with leading automotive manufacturers for joint development projects.

- Partnerships with technology firms to implement smart manufacturing solutions.

Impact on the Automotive Industry

Detroit Manufacturing Systems has made significant contributions to the automotive industry by providing high-quality components and innovative solutions. The company's focus on excellence has helped reshape manufacturing standards and set new benchmarks for quality and efficiency.

Statistics on DMS Impact

- Over 1 million components produced annually.

- Significant reduction in production time through advanced manufacturing techniques.

- High customer satisfaction ratings, reflecting commitment to service excellence.

Future Trends in Manufacturing

The future of automotive manufacturing is promising, with Detroit Manufacturing Systems poised to lead the charge. Key trends that will shape the industry include increased automation, the rise of electric vehicles, and a continued focus on sustainability.

Anticipated Developments

- Expansion into electric vehicle component manufacturing.

- Further investment in automation and smart manufacturing technologies.

- Increased emphasis on sustainable practices and eco-friendly materials.

Conclusion

In conclusion, Detroit Manufacturing Systems represents a beacon of innovation and quality in the automotive manufacturing landscape. With its commitment to excellence, sustainability, and technological advancement, DMS is well-equipped to navigate the challenges of the future. As the automotive industry continues to evolve, DMS will undoubtedly play a crucial role in shaping its trajectory.

We invite readers to share their thoughts on the future of automotive manufacturing in the comments below. If you found this article informative, please consider sharing it with others or exploring more articles on our site.

Thank you for reading, and we look forward to welcoming you back for more insights into the world of manufacturing and innovation!

Blue Rooster Lawrenceville: A Culinary Journey Through Flavor And Community

Exploring Juniper Valley, Colorado: A Hidden Gem In The Rockies

Blue Highway Games: A Unique Gaming Experience In Seattle, WA